What are the methods for machining precision parts?

2025-11-05

The machining of precision parts involves a wide range of processes, especially in the hardware machining industry. Today, Chenju Precision will answer some questions about the methods for machining precision parts.

Turning, milling, planing, shaping, grinding, drilling, boring, punching, sawing, etc. Other methods may include wire cutting, casting, forging, electro-etching, powder machining, electroplating, and various heat treatments.

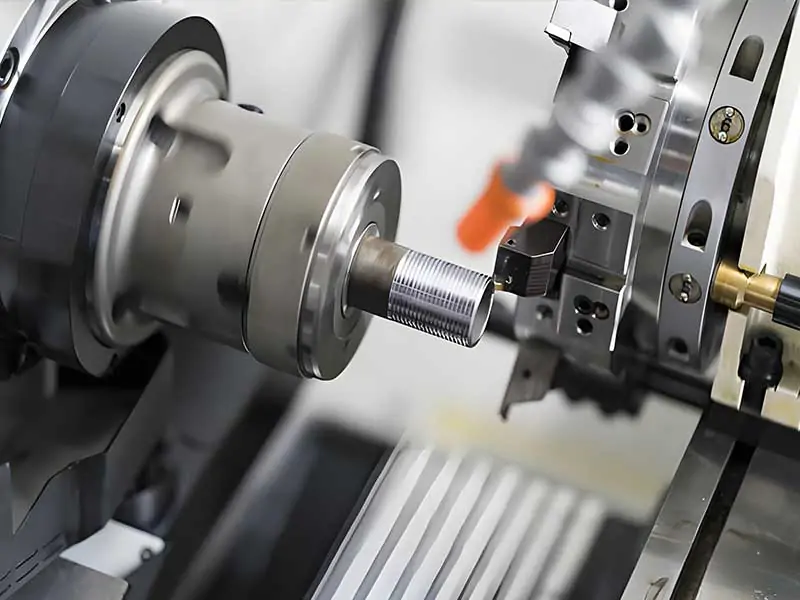

Lathe: Includes vertical and horizontal lathes; newer equipment includes CNC lathes, primarily for machining rotating bodies;

Milling: Includes vertical and horizontal milling machines; newer equipment includes CNC milling machines, also called machining centers; primarily for machining grooves and straight-line surfaces, but can also machine curved surfaces using two- or three-axis simultaneous machining;

Planking: Primarily for machining straight-line surfaces; normally, the surface roughness produced is not as high as that of a milling machine;

Shaping: Can be understood as a vertical planer, very suitable for machining incomplete circular arcs;

Grinding: Includes surface grinding, cylindrical grinding, internal grinding, tool grinding, etc.; used for high-precision surface machining, producing workpieces with exceptionally high surface roughness;

Drilling: Machining holes;

Boring: Primarily for boring internal holes using boring tools or inserts;

Punching: Primarily for forming shapes using a punch press, capable of punching round or irregularly shaped holes;

Sawing: Primarily for cutting using a saw, commonly used in the blanking process.

If you have any future projects requiring precision parts machining, please send your drawings to this email address for an evaluation and quote: info1@us.cjcncmachining.com