How to choose between true five-axis CNC machining and 3+2-axis machining?

2025-12-17

How to choose between true five-axis CNC machining and 3+2-axis machining?

In the field of high-end manufacturing, five-axis technology has become a powerful tool for processing complex parts. However, when faced with the two mainstream technologies of "true five-axis" linkage and "3+2-axis" positioning, many users feel confused when making a selection. In fact, there is no absolute superiority or inferiority between these two solutions; the key lies in precisely matching your processing requirements. Next, Chenju Precision will help you clarify the concepts and assist you in making the wisest investment decision.

I. Concept Differentiation: What is "True Five-Axis", and What is "3+2 Axis"?

First of all, we need to understand the essential differences between the two.

Five-axis machining center: It refers to the simultaneous interpolation movement of the X, Y, and Z three linear axes of the machine tool and two of the A/B/C rotational axes. During the machining process, the orientation and position of the cutting tool continuously change in space, thus enabling the processing of complex spatial free-form surfaces.

3+2-axis positioning machining: Essentially, it is based on three-axis machining. By tilting and fixing the workpiece at an optimal angle position through the rotary axis, three-axis milling is then carried out at this angle. The core lies in "positioning", and the rotary axis does not move in coordination during the cutting process.

In simple terms, five-axis machining is "dynamic processing", while 3+2-axis machining is "three-axis processing at static angles".

II. Capability Comparison: How to Make Choices Based on Core Requirements?

The type of your product and the requirements of your process directly determine which solution is more suitable.

When choosing a five-axis machining center, if your requirements are:

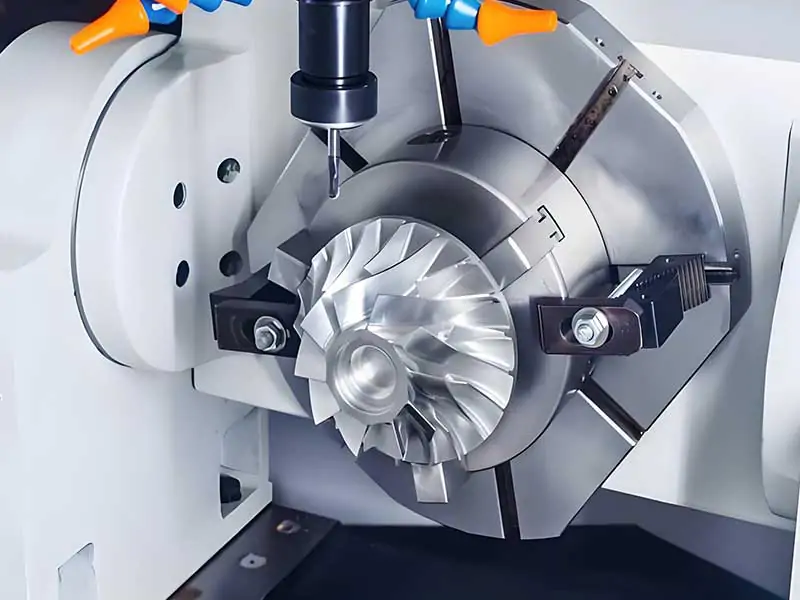

Complex spatial surface machining: This is the core application area of five-axis linkage. For parts with continuous complex surfaces such as impellers, blades, and engine integral casings in the aerospace field, as well as deep cavities and negative angles of high-precision molds, five-axis linkage technology must be used to achieve the processing.

Pursuing ultimate surface quality: When machining curved surfaces, five-axis linkage can adjust the tool axis orientation to enable the side cutting edge of the ball-end mill to participate in the cutting process, avoiding the area where the centerline speed of the tool tip is zero, thereby achieving a more consistent and smoother surface quality.

Choose 3+2-axis positioning processing if your requirements are:

Multi-angle feature processing: For box-type and disc-ring type parts, drilling, tapping, milling slots and other processing need to be carried out on multiple surfaces. The 3+2-axis method can complete the processing of five surfaces and multiple angles in one clamping, greatly improving efficiency and avoiding errors caused by multiple clamping.

Reducing tool costs and enhancing rigidity: By tilting the workpiece, the tool can operate at the optimal cutting angle. Shorter and more rigid tools can be used for deep cuts and high-speed, powerful cutting, which not only improves processing efficiency and quality but also extends the tool’s lifespan.

Cost-effectiveness priority: Generally, the cost of achieving 3+2-axis functionality is lower than that of a five-axis simultaneous machine tool of the same grade. For enterprises that do not require continuous five-axis simultaneous operation but have angular processing needs, this is a highly cost-effective solution.

Chenju Precision focuses on precision parts processing services, offering 3-axis, 4-axis, and 5-axis CNC machining, turning and milling compound processing, CNC lathe processing, and small-batch parts processing, etc. It excels in complex structural parts and can customize special fixtures and jigs for projects. Each product undergoes at least four full inspection procedures, with a quality pass rate of 99.93%. It provides high-quality small-batch processing customization services, with sample production within 3 days and delivery within 7 days.